NATIONAL HEAT TREATERS

Best Heat Treaters In Chennai

"Your Trusted Heat Treaters In Chennai"

At National Heat Treaters, we are committed to deliver premium solutions in Heat Treatment to cater to a wide range of industrial requirements. With our dedication to excellence, we strive to meet the highest standards in the industry

Who Are We?

With Over 25 Years of Experience

National Heat Treaters is a distinguished ISO 9001:2015 certified company, recognized by prestigious institutions such as IBR (Indian Boiler Regulations), BHEL, and BVIS. Our commitment to quality extends globally, as we collaborate with renowned inspection agencies like Lloyds, EIL, and DNV. With over 25 years of invaluable experience, National Heat Treaters excels in both heat treatment processes and furnace manufacturing, offering unparalleled expertise in the industry.”

CERTIFIED BY

Years Of experience

Plants

satisfied clients

furnaces

successful projects

(TONS) monthly productivity

Our Services

Stress Relieving

Stress relieving offers more benefits, including improved dimensional stability, reduced distortion, enhanced machinability, and increased resistance to fatigue and corrosion.

It involves heating the workpiece to a specific temperature, holding it at that temperature for enough time to reduce the stresses present in the material, and then cooling the material at a slow rate.

Normalising

We understand that every material and application is unique. That’s why we offer customized normalizing solutions tailored to your specific requirements.

Whether you need batch processing or individualized treatment, we have the expertise and flexibility to deliver results that exceed your expectations.

Annealing

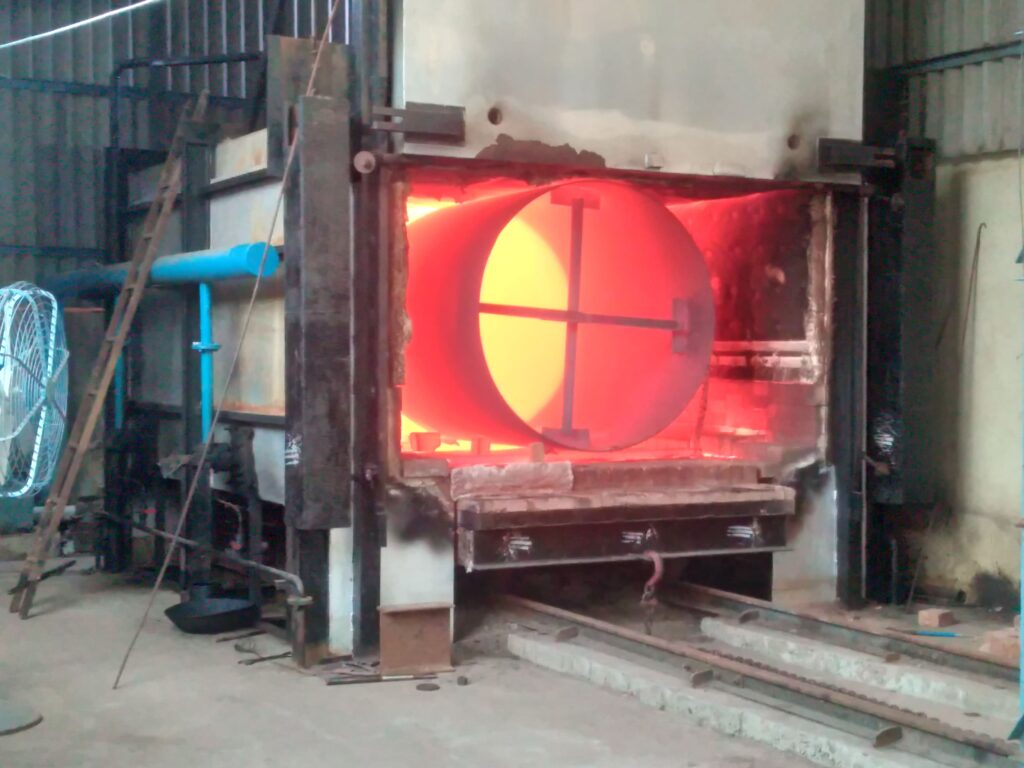

Equipped with cutting-edge furnaces and advanced technology, our facilities are designed to deliver precise and uniform heating and cooling during the annealing process.

We maintain controlled environments to guarantee the quality and consistency of our annealing services.

Solution Annealing

Solution annealing enhances the mechanical properties of materials, including strength, corrosion resistance, and ductility.

From initial material inspection to final product delivery, we conduct thorough quality checks to ensure the integrity and performance of your components.

Stress Relieving

Stress relieving offers more benefits, including improved dimensional stability, reduced distortion, enhanced machinability, and increased resistance to fatigue and corrosion.

It involves heating the workpiece to a specific temperature, holding it at that temperature for enough time to reduce the stresses present in the material, and then cooling the material at a slow rate.

Normalising

We understand that every material and application is unique. That’s why we offer customized normalizing solutions tailored to your specific requirements.

Whether you need batch processing or individualized treatment, we have the expertise and flexibility to deliver results that exceed your expectations.

Annealing

Equipped with cutting-edge furnaces and advanced technology, our facilities are designed to deliver precise and uniform heating and cooling during the annealing process.

We maintain controlled environments to guarantee the quality and consistency of our annealing services.

Solution Annealing

Solution annealing enhances the mechanical properties of materials, including strength, corrosion resistance, and ductility.

From initial material inspection to final product delivery, we conduct thorough quality checks to ensure the integrity and performance of your components.

Call Us For A Quality Service

If You Have Any Queries Related To Heat Treatment And Other Related services, Call Us

Our Work Space