Services We Offer

You will be satisfied with our quality services

Services

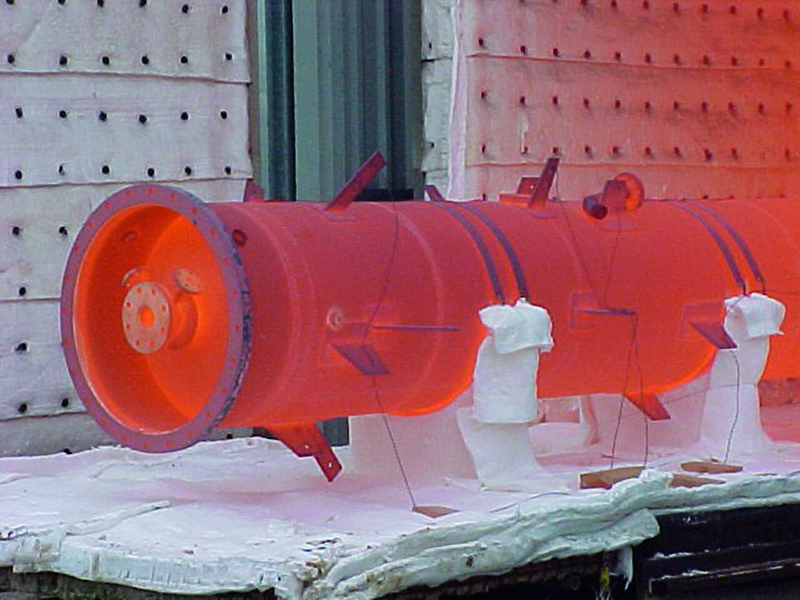

We specialize in stress relieving services for boilers, pressure parts, upper and lower housings, steel rollers for steel plants, power plants, and cement industries. Additionally, we provide stress relieving for turbines, stators, and rotors for windmills, header boxes, and heat exchangers for airfin cooler plants. Our services extend to impellers and turbines for hydropower stations, stainless steel dished ends for atomic power stations, flanges, AFT end cones for aerospace, as well as brakes and side frames for the Integral Coach Factory of Indian Railways.

Furthermore, we offer annealing services for bars and coils catering to various automobile industries. Additionally, we specialize in normalizing steel castings and forming dish ends for leading industries

FURNACE

Bogie Hearth Oil Fired Furnace -01 No

(8.0 mtr(L) x 4.0 mtr(W) x 3.5 mtr(H)

Bogie Hearth Oil Fired Furnace -01 No

(6.5 mtr(L) x 3.2 mtr(W) x 2.2 mtr(H)

Bogie Hearth Oil Fired Furnace -01 No

(3.5 mtr(L) x 2mtr(W) x 1.5 mtr(H)

Chamber Type Electrical Furnace -01 No

(850 mm(L) x 450 mm(W) x 250 mm(H)

Our Quality Services

Stress Relieving

Stress relieving offers more benefits, including improved dimensional stability, reduced distortion, enhanced machinability, and increased resistance to fatigue and corrosion.

It involves heating the workpiece to a specific temperature, holding it at that temperature for enough time to reduce the stresses present in the material, and then cooling the material at a slow rate.

Normalising

We understand that every material and application is unique. That’s why we offer customized normalizing solutions tailored to your specific requirements.

Whether you need batch processing or individualized treatment, we have the expertise and flexibility to deliver results that exceed your expectations.

Annealing

Equipped with cutting-edge furnaces and advanced technology, our facilities are designed to deliver precise and uniform heating and cooling during the annealing process.

We maintain controlled environments to guarantee the quality and consistency of our annealing services.

Solution Annealing

Solution annealing enhances the mechanical properties of materials, including strength, corrosion resistance, and ductility.

From initial material inspection to final product delivery, we conduct thorough quality checks to ensure the integrity and performance of your components.

Call Us For A Quality Service

If You Have Any Queries Related To Heat Treatment And Other Related services, Call Us